At first glance, a folding box looks simple.

However, when it closes with a clean “click”, smart structure is already at work.

At the top of this page, a short video or photo shows the box closing by itself.

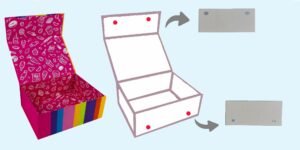

Instead of using hooks or tape, the box relies on internal components.

Specifically, a small iron plate sits inside the lid.

At the same time, a small magnet is fixed inside the front panel.

When the lid comes down, magnetic force pulls the two parts together.

As a result, the box closes automatically and precisely.

This is how a magnetic folding box closure works.

Why We Use Magnet and Iron for Folding Boxes

This structure is not chosen by chance.

In practice, magnet and iron offer clear advantages.

First, the opening and closing experience feels smooth and controlled.

Second, the lid stays flat and aligned after repeated use.

More importantly, the exterior remains clean with no visible hardware.

From a production point of view, this structure performs consistently.

Therefore, it suits mass production and premium packaging at the same time.

This is why we apply it to many folding box projects.

Inside the Box: Key Components Explained

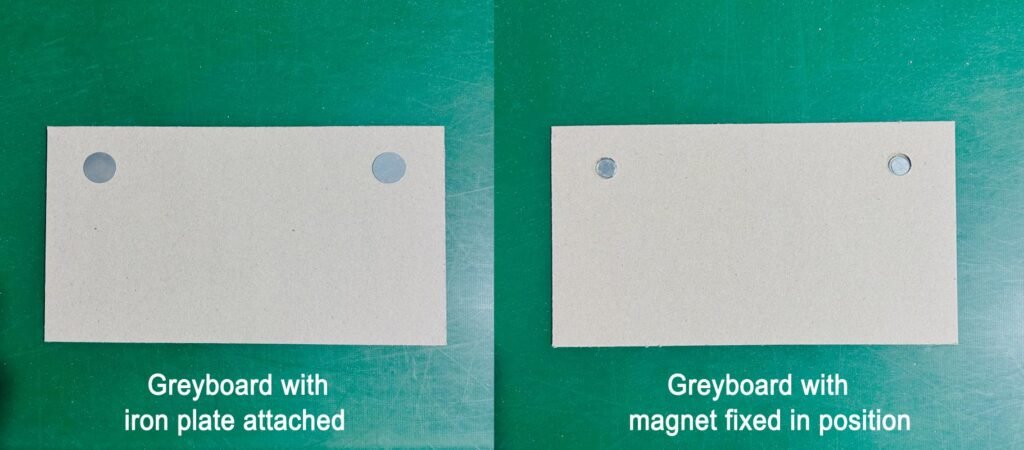

Before wrapping paper or applying any surface finishing, the greyboard must be prepared.

At this stage, the closure system is built directly into the structure.

The following table explains each component and its role.

| Component | Installed Position | Function | Key Control Point |

|---|---|---|---|

| Iron plate | Inside the lid | Receives magnetic force | Accurate alignment |

| Magnet | Inside the front panel | Creates attraction | Correct polarity |

| Greyboard | Box structure | Holds all components | Thickness tolerance |

| Glue | Between parts and board | Fixes plate and magnet | Bonding strength |

Each component interacts with the others.

If alignment or bonding fails, the closing feel changes immediately.

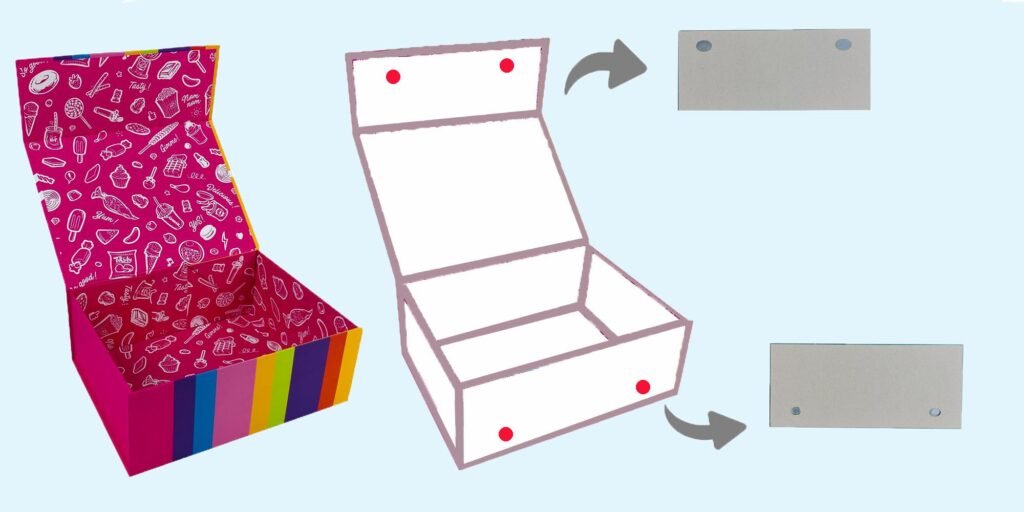

Visual Reference Before Paper Wrapping

At this point, we usually show two reference photos again.

Together, these visuals help readers understand the hidden structure.

As a result, it becomes easier to imagine how the lid and front panel connect after wrapping.

This step also reduces misunderstanding during sampling discussions.

How We Attach the Iron Plate to the Greyboard

Before box assembly begins, the iron plate is fixed to the greyboard.

First, glue is applied evenly.

Next, the plate is pressed firmly into position.

Placement accuracy is critical.

Even a small offset can weaken the magnetic response.

For this reason, this step is inspected carefully because it directly affects the magnetic folding box closure quality.

How We Attach the Magnet to the Greyboard

Compared with the iron plate, the magnet requires stricter control.

Before bonding, polarity is confirmed.

After that, depth and position are adjusted precisely.

Only after testing the attraction do we move to the next step.

This process ensures stable and repeatable closing performance.

Magnet Closure Compared with Other Folding Box Closures

Clients often ask how magnet closure compares with other options.

In comparison, the differences are clear.

| Closure Type | Closing Feel | Durability | Appearance | Production Control |

|---|---|---|---|---|

| Magnet + iron | Clean and crisp | High | Invisible | High |

| Velcro | Rough | Medium | Visible | Low |

| Ribbon tie | Soft | Low | Decorative | Medium |

| Tuck-in flap | Basic | Medium | Simple | High |

Especially for premium packaging, magnet closure offers the best balance between feel and reliability.

Simple Boxes Still Require Smart Design

Paper boxes may appear simple.

In reality, production involves many small decisions.

Every layer affects alignment.

Every millimeter affects closing force.

During development, opening angles are tested.

At the same time, long-term use is considered.

This approach ensures that the structure works beyond the first impression.

Why This Closure Matters for Your Brand

Ultimately, customers remember how a box feels in their hands.

They also remember the sound and resistance when it closes.

A well-designed magnetic folding box closure improves perceived value without adding complexity.

Therefore, it supports both brand image and user experience.

This is how we approach folding box production.

And this is why the details matter.

If you want to see more folding box structures and production details, you can visit our folding box page on our official website.

https://www.chiefcolor.com/product-category/packaging-styles/foldable-rigid-boxes_c3