As a paper box and paper bag manufacturer with over 20 years of production experience, we’ve seen paper box manufacturing automation transform almost every part of the packaging industry. Printing, laminating, die-cutting, mounting—these processes have become faster and more precise in paper box manufacturing thanks to advanced machinery.

However, one stage used to remain highly labor-dependent: final packing.

To better support overseas clients who require stable quality, clean packing, and reliable delivery timelines, we have gradually upgraded our production lines with automated PP bag packing and automatic carton sealing machines. These systems allow us to complete the last step before shipment with greater speed, accuracy, and consistency.

1. Why Final Packing Matters in Custom Box Production

For every order, once rigid boxes or foldable cartons are completed, the final packing stage includes:

- Counting finished boxes

- Inserting them into PP bags for dust protection

- Packing them into corrugated cartons

- Sealing the cartons for shipment

These steps seem simple, but they play a crucial role in ensuring your custom packaging arrives clean, protected, and consistently packed.

When done manually, these common issues often occur:

- Inconsistent box quantities per bag or carton

- Uneven PP bag packing or excess wrinkles

- Carton sealing pressure varying from one operator to another

- Increased labor cost during peak seasons, leading to slowdowns

To make sure every carton our clients receive is consistent and up to standard, we decided to upgrade these “simple but quality-critical” steps across our paper box manufacturing automation production lines.

2. How Automation Improves Stability and Output Quality

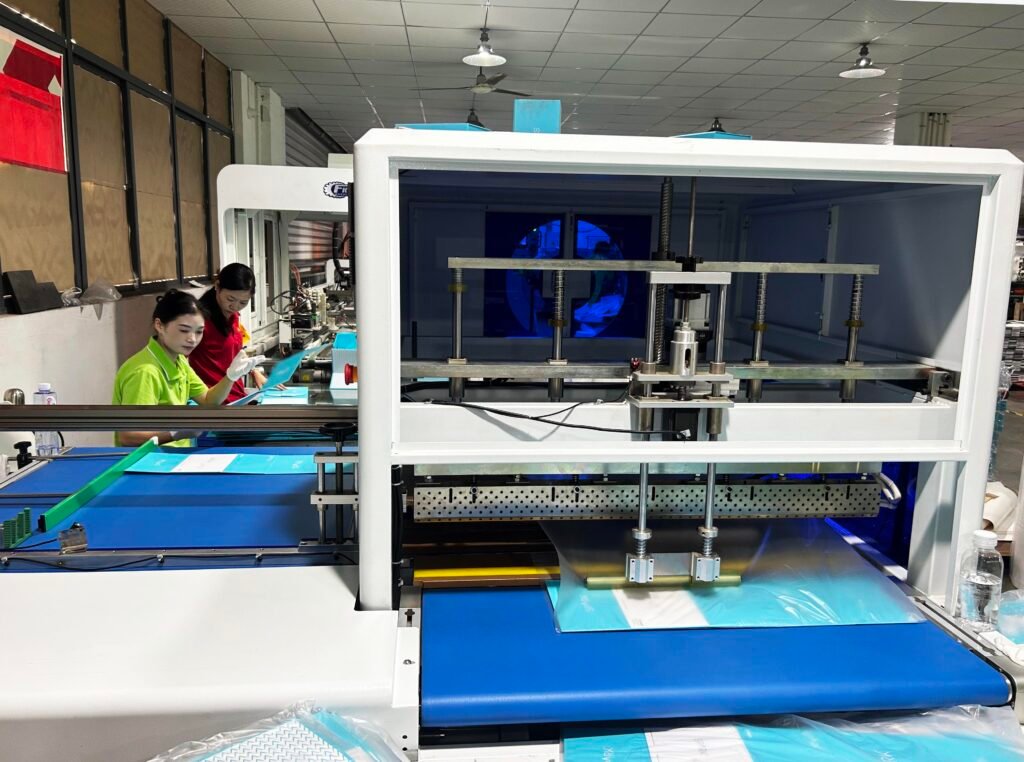

After introducing automated PP bag packing and carton sealing machines, our packing efficiency and consistency improved immediately. Below are two demonstrations from our factory:

PP Bag Packing Machine Demonstration

Our machine automatically forms plastic bags from film rolls, inserts custom gift box precisely, and ensures clean, tight packing—perfect for gift boxes and cosmetic boxes that need dust-free protection.

Automated Carton Sealing Machine Demonstration

This machine folds the carton flaps, applies transparent tape evenly, and completes sealing with consistent pressure—reducing human error and speeding up dispatch preparation.

Given the challenges of manual final packing, the benefits of automation become clear. Below is a comparison table of manual versus automated final packing, along with demonstration videos to help provide a clearer understanding.

Comparison Table

| Process Step | Manual Method | Automated Method | Benefit |

| Counting | Performed by workers; inconsistent | Sensor-based automatic counting | Higher accuracy |

| Bag Insertion | Labor-heavy and slow | PP bag packing machine | Faster and stable output |

| Carton Sealing | Uneven, slower | Automated carton sealing | Uniform and secure |

| Labor Demand | Requires multiple workers | Reduced by 70–90% | Lower operating cost |

| Output Stability | Varies by worker | Machine-stable | Predictable production |

| Error Rate | Medium to high | Near-zero | Better quality control |

3. How Automation Strengthens Our Capability as Your Paper Packaging Supplier

By applying automation to the final packing stage, we can confidently support large-volume and urgent orders while keeping quality consistent:

- 2–3× higher packing efficiency

- More stable and predictable daily production capacity

- Lower error rate during shipment preparation

- Cleaner, more uniform packing—important for luxury packaging

- Greater reliability for seasonal order surges

For international clients who expect both quality and punctual delivery, paper box manufacturing automation helps us maintain the professionalism and consistency your brand deserves.

Conclusion

As a manufacturer specializing in custom boxes and packaging, we believe that automation is more than just increasing speed—it’s about delivering stable, clean, and reliable final packing quality for every custom gift box order.

By integrating PP bag packing and automatic carton sealing systems into our production line, we ensure that your packaging arrives in perfect condition, ready for assembly or retail display.

If you’d like more information about our production capabilities or want a customized demonstration, feel free to contact us anytime. We’re happy to share our expertise.